Facility Design

Facility Design

Facility design is planning how your building, grounds, equipment, utilities, tools, utensils, vehicles, and personnel will interact, in a manner to prevent risks of contaminating your products during production.

Remember, it is always better to prevent risk than to react to risk, and sanitary design is a powerful preventive measure and a first line of defense against many types of contamination risks.

Facility design includes the following considerations:

- Preventing contamination and sanitation issues at the site, including: pest infestations, airborne contaminants, drainage issues and other contamination concerns.

- Providing sufficient space for all activities, and adequate segregation of processes, to avoid cross-contamination during production.

- Facilitating the easy and effective cleaning and maintenance of facilities and equipment.

- Selecting wall, floor, and ceiling surfaces that match the requirements of each area in the facility.

- Using facility design to create barriers between production areas and external areas and to regulate the traffic of equipment, people, pests, and product.

- Choosing equipment and utensils with product-contact surfaces that are easily cleanable, durable, non-absorbent, and non-toxic.

- Installing and maintaining equipment in a way that allows for the proper cleaning, maintenance, and inspection of the equipment.

- Using appropriate plumbing systems designed to prevent backflow

- Using appropriate HVAC systems designed to reduce airborne contaminants and otherwise control the environment.

In this training, we will address the above considerations in the following format:

- Location and Outside Grounds

- Building Design and Layout

- Ease of Cleaning and Maintenance of Facility

- Selecting Wall & Floor Surfaces

- Using Doors as Barriers

- Equipment & Utensils

- Installing and Maintaining Equipment Cleanliness

- Plumbing Systems

- Ventilation

Location and Outside Grounds

Maintaining a sanitary processing environment inside the facility starts with maintaining a sanitary environment outside the facility.

The grounds around your facility should be well-defined and under your control. You should inspect the outside grounds regularly for:

- Landscaping issues

- Standing water

- Proper waste storage and removal

- Unsanitary storage of debris, obsolete materials, waste, or junk

- Neglected or run-down buildings

- Pest attraction issues

- Issues from neighboring properties

First, let’s talk about landscaping. The use of vegetation such as grass, bushes, trees, and shrubs can really improve the appearance of your facility, but they can also create a great shelter or hiding place for pests. To prevent harboring pests, keep the vegetation away from the building, and keep the vegetation clear at the ground level.

Also, your grounds should be designed for the proper control of water. Ensure that yards are well drained and that drives, parking lots and sidewalks are paved correctly. Be aware of flood risks in the event of an unusually strong downpour. Ensure that the roof provides for adequate and controlled drainage through the grounds and away from the facility. Avoid standing water as it draws pests and often results in tracking mud and other contaminants into the facility.

Waste storage and removal is another important consideration. Store outside waste in a location away from the building and other contamination points. Properly maintain and cover outside waste containers to prevent leakage and pest harborage. Regularly empty the waste containers, frequently enough to avoid the build-up of excess waste. Keep the areas around waste containers clean and free of spillage so as to avoid drawing pests. Cleaning is made easier if the waste containers are placed on a concrete pad or paved area, and if a water faucet or hydrant is nearby, or a power-washer is available.

Avoid the build-up of debris, obsolete items, or other waste or litter anywhere else on the grounds. Maintain or tear down neglected or run-down buildings. Place outside storage so as to prevent pest harborage and protect the equipment, materials, or other items from deterioration or contamination.

When inspecting your grounds, look for anything that can draw pests. Even lights may attract insects to the building at night. Ensure that outside lights are mounted in invulnerable locations or away from the building to avoid drawing insects to vulnerable places. Ensure that there are no holes in exterior walls that would allow for the entrance of pests.

Neighboring properties can also present issues for your site. Preferably, you should choose a site with neighbors that are not likely to present risks. However, you should regularly inspect your grounds and surroundings for changes that might present a risk. Look for strange circumstances that would present unexpected risks, but also look for the same issues as you would look for on your own site, such as run-down buildings, debris, poorly maintained vegetation, standing water, nearby farming, ranching or dairy operations, irrigation ditches that could carry contamination, and so forth. If there are issues, seek a mutually agreeable resolution with your neighbors.

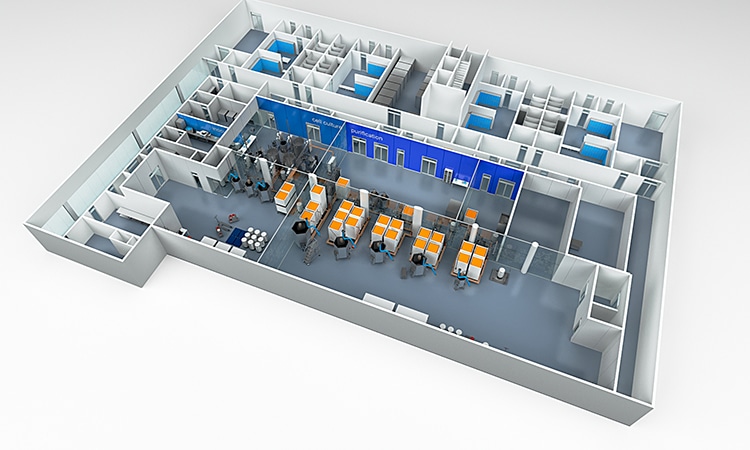

Building Design and Layout

Building design, and proper plant layout are key factors in sanitary design.

Understanding your product, the production process, and their risks, is a necessary first step to sanitary design. Your design should support your efforts to control the risks of your particular product and process.

Some helpful inputs for creating a sanitary design include the following:

- Product risk assessment (including critical quality attributes or your product and their control parameters)

- Process flow diagram (showing inputs, activities, controls, outputs of your process)

- Process flow narrative (describing the people-centric — activities, including movements, tools used, tasks performed, communications made, etc.)

- Block flow diagram (showing the functional and transition areas, including the division of these areas into zones based on risk or hygiene requirements, for example.)

- Room criteria cards (showing the basic requirements for each room, including hygiene requirements, cleaning requirements, activity requirements, equipment requirements, utensils used, safety issues, etc.)

- Equipment layout and equipment specifications, and

- Other flow diagrams (including for raw materials, ingredients, in-process materials, final product, airflow, waste, chemicals, people, and vehicles etc.)

The above inputs are necessary for a complete understanding of your product and processes. A complete understanding of your product and processes is necessary to understand your unique production risks. Understanding these unique production risks is necessary for proper facility design. And proper facility design will result in a more efficient operation, reduce risks of cross-contamination, and minimize safety concerns and accidents. I have seen many facilities built in haste without adequate consideration for sanitary design, and the costs of this mistake can be very high indeed.

As far as equipment goes, keep in mind that you will need to understand the operational, maintenance, and cleaning requirements for your equipment in order to properly design your facility. This information should be provided to you in the form of a turnover package from the equipment manufacturer. Ensure that you are provided with this important information and that it informs you, and your architects, and engineers during the design of your facility. Provide adequate space for the powering, maintenance, inspection, cleaning, and operation of your equipment. Place your drains, water or air supply, and electrical as need to operate the equipment as per specifications.

Some other general layout tips include the following:

- Locate locker rooms and rest rooms near employee entrance points.

- Locate utensil- and handwashing sinks at convenient locations to promote their use. Also provide space for hand soap, towel dispensers or air dryers, and waste bins.

- Arrange production flows to minimize the handling and moving of materials and equipment.

- Segregate raw ingredients from finished materials.

- Separate the path of materials and product from the path of waste and chemicals.

- Separate employee traffic areas from vehicle or equipment traffic areas.

- Separate areas where mixing, sifting, filling, sealing, and packaging occur from production areas.

- Identify wet and dry manufacturing and cleaning areas and place barriers to prevent moisture and dust from traveling between areas.

- Design the layout so that air handling systems can easily remove contaminants, control airflow, and prevent mold and condensation problems.

- Provide airlocks where necessary to protect sensitive areas from harmful airflow.

- Provide adequate lighting throughout the facility.

A very long facility checklist for GMP sanitary design is available to you as part of this course. You can use it as an input for your sanitary design, and then later as an inspection checklist once your facility is up and running.

Ease of Cleaning and Maintenance of Facility

Your facility should be easy to clean and maintain. Here are some tips:

Use light colors for floors, walls, and ceilings whenever possible. This allows contamination on these surfaces to be easily spotted and immediately resolved. Also, use plenty of lighting. A well-lit facility improves productivity, security, safety and sanitation, and employee morale.

Maintaining floor perimeters is an important element for organization and cleaning needs. For storage areas, provide an 18-inch perimeter between rows of stored material, and between stored material and the wall. This will allow room for inspections, cleaning, and maintenance, as well as for placement of pest control devices. If adequate space is not available, racks can be installed right against the wall to keep items well above the floor and still allow access for cleaning, maintenance, and pest control.

Ceilings pose a great risk for contamination. Ceilings are full of pipes, conduit, and ductwork which which are not easy to clean or maintain. Also, ceiling heights are usually an issue because they are higher and harder to reach. For these reasons, a ceiling is a likely place for the accumulation of dust, condensation, bacteria, mold, or pests. Contamination from overhead is a real risk. The careful selection and installation of the right ceiling can provide a barrier from contamination and a platform for the easy cleaning of overhead utilities. Have a clear plan for creating a barrier to overhead contamination and for cleaning your ceilings.

Windows are another important consideration as part of your facility’s design; however, they are often overlooked during the design process. Windows may create natural lighting to brighten the workplace, but they also present facility hygiene and product quality issues by allowing passage for birds, insects, dirt, bacteria, and other airborne contaminants. Even if windows have screens installed to prevent pest entry, these screens will not prevent dirt, bacteria, and mold from entering the building. Also, some windows are temperature-sensitive and form condensation when the temperature fluctuates. Mold growth is likely to occur around these types of windows. Any kind of window should be added to the master cleaning schedule and also monitored according to the guidelines of your glass, brittle plastics, and ceramics program.

For rooms that will employ a wet sanitation process, ensure that drains are located in appropriate places. Ensure that ventilation can handle the moisture levels. Ensure that building materials are selected that suit the cleaning methods. Cleaning involves four factors that impact the materials you choose: Concentration of chemicals, temperature, mechanical force, and time.

Locate utensil sinks of sufficient size in convenient places for cleaning parts, utensils, and equipment. Locate racks nearby for safe and sanitary drying.

As you can see, there are a lot of components to keep in mind when thinking about how you will keep your facility maintained and cleaned to meet industry standards. You will need to document all of your cleaning and sanitation plans and keep a record each time they are completed.

Selecting Building Materials

Selecting Floor Surfaces

Flooring gets more abuse than any other area of a building. With continuous traffic, movement of equipment, exposure to water and spillage, the risk of deterioration and damage is high. Once deterioration begins, more water and debris tend to accumulate, which contributes to further damage and causes unsafe working conditions and poor sanitation.

Appropriate floor construction materials are selected based on the operations and requisite durability. Operational conditions which affect floor surface choices include, for example:

- Cleaning requirements (chemical concentration, temperature, mechanical force, and time)

- Vehicles and other traffic

- Type of machinery

- Type of products

In short, the floor must be easy to clean, and able to withstand the expected traffic load and the cleaning chemicals, equipment, and products used.

There are many different types of flooring to consider.

- For a warehouse or distribution center, a concrete floor surface with a sealant is typically best.

- For wet processing environments monolithic epoxy with aggregates or single membrane coating systems are generally acceptable.

- For offices and employee welfare areas, common flooring materials are acceptable, such as vinyl, asphalt tile, carpet, and linoleum. These are not recommended for use in production areas.

A major failure point for any floor surface is surface preparation. Ensure that your contractor takes adequate time and resources for proper floor preparation and uses the appropriate subfloor materials.

Selecting Wall Surfaces

Walls are another area where material choice is important. Materials used to create walls must be able to withstand abuse and the conditions of the work environment. Operational conditions which may affect wall surface choices include:

- Cleaning requirements (chemical concentration, temperature, mechanical force, and time)

- Piping and electrical needs

- Movement of personnel and vehicles

- Contamination risks

All walls must be easy to clean to prevent dirt accumulation. Walls with a smooth, high gloss finish and a light color are best. The seam between the wall and the floor should be curved and seamless to prevent accumulation of dirt and permit easy cleaning. Walls with rough textures, cracks, pits, or seams should be avoided. Exposure to heat, cold, water, chemicals, and so forth will eventually produce wear, so consider using a wall surface that can be easily repaired or replaced over time.

Wall surfaces to consider include:

Heavy-weight non-porous concrete, poxy coating systems, structural insulated panels or SIP, fiberglass, plastic, metal panels.

Selecting Ceiling Materials

Materials used for the ceiling must be able to withstand abuse and the conditions of the work environment. Operational conditions which may affect ceiling choices include:

- Ceiling and utility access requirements

- Cleaning requirements (chemical concentration, temperature, mechanical force, and time)

- Integration of light fixtures

- Contamination risks

For example, if wet processing is used, the ceiling must be able to withstand the moisture and chemicals used in cleaning. Knowing the maintenance and cleaning requirements in each room will help you make the right decision.

Ceiling system variants include:

Metal clamped cassette ceilings, band grid ceiling, gridless monoblock ceiling.

Selecting Light Fixtures

Glass poses a serious risk of foreign material contamination, so when selecting light fixtures go for shatter resistant bulbs, or protect the bulbs in a plastic fixture, or employ some other strategy to ensure that broken glass cannot contaminate raw material, packaging, processing equipment, or finished product. Identify and regularly inspect all glass in your facility to ensure no breakage and contamination has occurred. This includes glass in production zones, such as glass on found on meters and gages, that must be inspected as part of pre-operations inspections.

Using Doors as Barriers

Using doors as barriers inside a facility will help direct the flow of equipment, people and product, and keep contamination out of production areas.

Doors should not open directly into sensitive production or storage areas. Keep in mind that employees often leave doors open or unattended. A common solution is to provide a double set of self-closing doors to ensure that there is always a barrier between the sensitive area and the outside area.

Restroom doors are another consideration. Toilet facilities should not open directly into a production area. Again, a double-door entrance with self-closing doors can be used. The space between the doors should be long enough that a person cannot hold both doors open at the same time. Another solution is to have the toilet room open into a locker room, that in turn opens into the processing area.

There are a large variety of doors that can be used. Each has advantages and serves specific purposes.

Strip doors can create a degree of temperature and humidity control between rooms, but they do not seal well and require cleaning as they are constantly brushed against. If an airtight seal and very clean surface is required, then strip doors are not a first choice.

Roll-up or rapid roll doors are more commonly used as effective barriers between areas of a facility. These doors can be equipped for easy and quick opening and closing by forklift or equipment operators, and can provide a good seal to prevent the passage of contaminants from one area of the plant to another.

Bi-fold doors can also open and close quickly, provide adequate protection between work areas, save energy, and be easily maintained.

Pedestrian doors should be installed next to any large doorways used for vehicle traffic in order to separate the path of personnel and vehicles and reduce potential accidents.

All perimeter doors should be tightly sealed to prevent dirt, pests, and other contaminants from entering the building. Perimeter doors should also provide security against unauthorized access to the facilty. Exit doors should be clearly marked and allow for quick, safe, and unobstructed exit.

Restroom Requirements

Rooms with toiletsToilet rooms should not open into a production area. Toilet rooms should have relative negative air pressure to other areas of the facility to ensure that the air does not escape when doors are open. Toilet rooms should ventilate air to the outside using an an exhaust fan. Hand washing stations must be provided for all toilet areas. These stations must supply hot and cold running water, hand soap, towels or some other hand drying device, and covered waste containers. In some jurisdictions, sinks in bathrooms are required to have a hands-free or fingerless valve for the sink. Hand washing signs should be posted in all the toilet rooms.

Equipment & Utensils

Utensils are implements or containers used in the storage, preparation, transportation, dispensing, sale, or service of the product. Examples of utensils include knives, sifters, totes, chutes, belts, gloves, boards, and tables. All utensils should be designed to facilitate easy cleaning, maintenance, and the prevention of shedding parts or material into the product.

Utensils can be a potential source of biological, chemical, and physical contamination. Utensils that have not been properly sanitized are a common source of biological contamination such as E. coli, Listeria, and Salmonella.

“Equipment” means an article that is used in the operation of the production process, such as a freezer, grinder, hood, ice maker, mixer, oven, sink, and so forth.

Chemical hazards from processing equipment range from lubricants, gearboxes, bearings or hydraulic fluid to overhead lines. Physical hazards may include metal fragments and machinery parts such as nuts and bolts. Equipment can also be a potential source of biological contamination. Equipment that has not been properly sanitized is a common source of biological contamination such as E. coli, Listeria, and Salmonella.

Almost all equipment and utensils contain direct and indirect product-contact surfaces. A direct contact surface is any surface that comes in direct contact with the product. An indirect contact surface is any surface nearby a contact surface where product residue or potential contaminants may collect and find their way into the product.

All contact surfaces should be easily cleanable, durable, non-absorbent, and non-toxic. Suitable, non-corrosive materials should be used. Select equipment that is easy to disassemble for cleaning and sanitizing activities. Smooth welds will prevent ingredient or product buildup.

Some materials should be avoided in a GMP facility. Wood should be avoided because it absorbs liquid, produces odor, is porous, and cracks. Thus, it is difficult to sanitize, likely to shed splinters, and, with so many other options, an unnecessary risk. Some types of stainless steel should be avoided because they can corrode. A common stainless steel type for GMP applications is type 304 stainless steel. This steel is preferred because it is particularly resistant to oxidization and corrosion. Also, be selective in choosing coating systems for equipment, utensils, and areas of the facility. Coating systems can leach contaminants, or peel, or create other hazards.

Installing and Maintaining Equipment

When purchasing new equipment, perform a review of the equipment against GMP requirements and known risks to ensure that it will enhance the sanitary design of your processes and facility. Often GMP facilities will employ an Equipment Selection Checklist, or an Equipment Commissioning Checklist, to ensure that equipment will meet GMP requirements.

Operational conditions which may affect equipment choices include:

- Cleaning requirements

- Such as, can it withstand the chemical concentration, temperature, mechanical force, and time of your cleaning procedure

- Also, is it easily disassembled and cleaned or cleaned in place, is it elevated for easy cleaning beneath and spaced for easy cleaning all around

- Also:

- Is the equipment made from non-corrosive and non-toxic materials?

- Does the equipment present any risk of depositing broken parts into the product?

- Does the equipment have smooth seams to prevent material build-up?

- Does the equipment protect product against leaks of lubricant, fuel, or other contaminants?

- Also, consider:

- Maintenance requirements

- Inspection requirements, and

- Space for inspections, cleaning, and maintenance, and

- Congruence with the surrounding area

Before and after installation of new equipment, conduct tests to verify that the equipment will function as expected. Verify that your planned cleaning procedure will work as well. For pharma applications, you will need to do a very thorough and well-documented equipment qualification process – this will be covered in another video.

Plumbing Systems

Water quality

Potable water is water that is safe for consumption. Public water systems remove certain impurities and contaminants and provide potable water that is suitable for some GMP purposes. However, especially when water is used as an ingredient, higher standards of quality may be required.

For example, a reverse osmosis system removes sediment and chlorine from water that would otherwise exist in a public water systems. Water used as an ingredient to your product should be of a defined quality standard and should be tested or monitored regularly to verify that it meets that quality standard. Quality is often defined in terms of chemical, physical and microbiological quality. Water systems should be designed to avoid stagnation and risk of contamination, and to be routinely cleaned and sanitized to ensure that there is no biofilm build-up.

Select the level of water quality, and the corresponding water system, that will ensure a safe product.

Proper plumbing for sewage

Ensure that your water and sewage systems are designed to prevent the possibility of sewage water contaminating potable water. Here are some tips:

- Backflow preventers should be used to prevent back siphonage of contaminated water into potable water.

- Sanitary lines must not discharge into contaminated lines. For example, restroom plumbing should not be connected with process drains, such as floor drains.

- Contaminated lines must not be installed above any production area or storage area, or near any processing equipment, or along any path of materials, ingredients, or packaging, as contamination from these lines will cause illness.

Placement of drains

Proper drainage from the production floor is often a neglected consideration during the design phase. Ensure that your drains are properly located throughout your facility. Here are some tips:

- Define your cleaning requirements before designing your drainage system. Locate drains as required by the cleaning strategy.

- Locate drains with sloped floors for easy clean-up and to avoid standing water.

- As a general rule choose drains that are small and easy to clean to prevent contamination. Grates should be installed over drains in wet processing or wash areas. Grates should be easy to remove for cleaning purposes.

- Locate drains in relation to equipment for easy access and to reduce risk of backpressure contaminating sensitive equipment or areas.

- If you have submerged water lines, then risk of back siphonage is higher. Avoid submerged lines or install vacuum breakers to prevent back siphonage.

- As always check and follow your local code.

Ventilation

Properly installed ventilation systems:

- Reduce moisture and condensation

- Reduce dust accumulation

- Remove heat and moisture through evaporation and exhaust

- Remove airborne particulates

- Help control sanitary airflow through the facility

Identify hazards such as areas with high dust, moisture, and heat, for example. Ensure that your system is designed to handle these risks.

Properly installed ventilation systems also prevent cross-contamination of air from dirty areas to clean areas. Air should always flow from clean to dirty spaces, rather than from dirty to clean. This is controlled by having higher air pressure in cleaner areas of the facility, thus pushing the air out from the clean area to the dirty area. When a door leading to a clean area is opened, you should feel air rushing out.

If you have an environment with hazardous fumes, ensure that you follow local code. Air replacement rates should be sufficient to keep the air safe and clean from all hazards.